PRODUCT CATEGORY

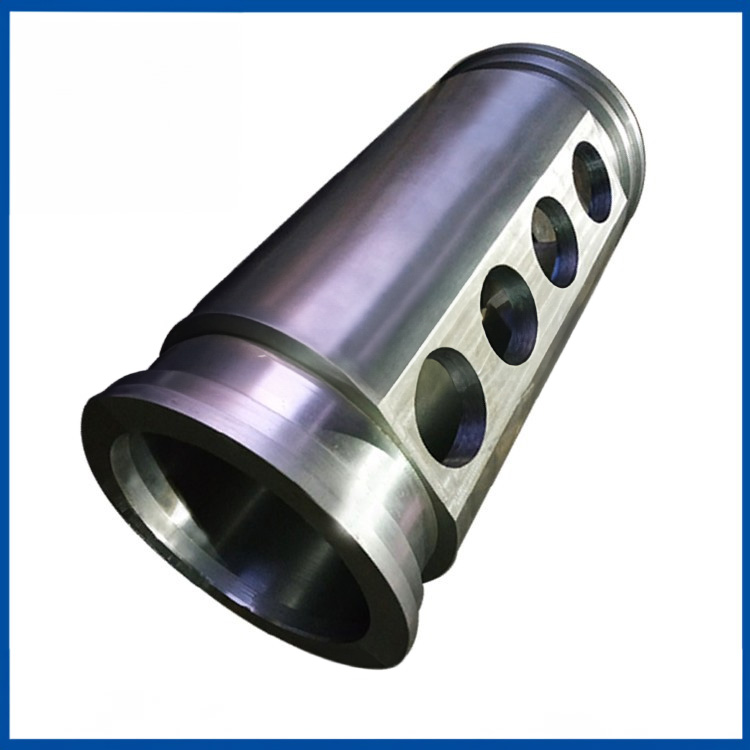

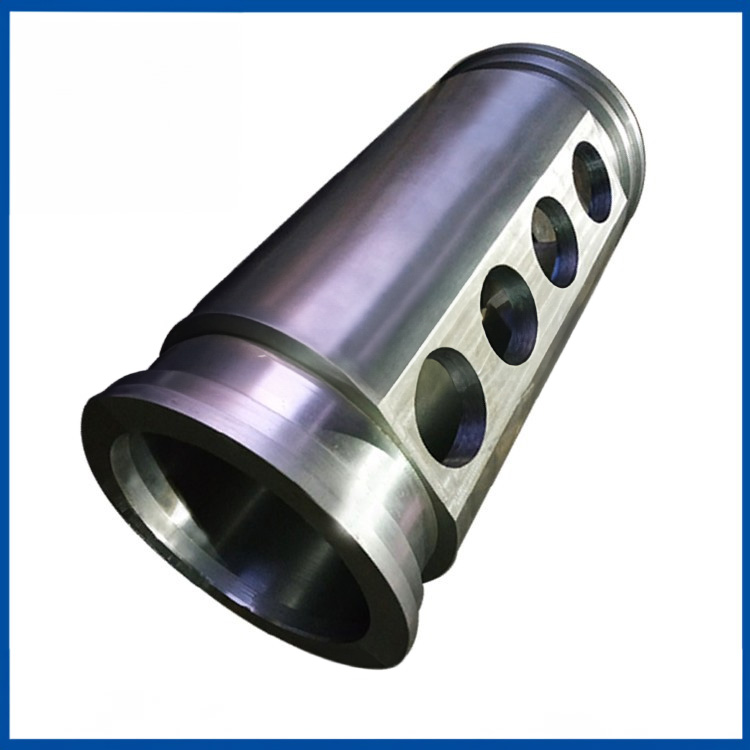

Forged Components for Mud Pump Casings

Forged Components for Mud Pump Casings

Mud pump casings are vital parts of drilling rigs, primarily used in the oil and gas industry. They house the pump mechanism that circulates drilling fluid (mud) to cool the drill bit and carry cuttings to the surface. Forged components for mud pump casings offer several advantages due to their strength and durability.

Key Features

High Strength: Forged casings are made from high-quality materials, providing excellent tensile strength and resistance to wear and tear.

Pressure Resistance: Designed to withstand high pressures encountered during drilling operations, ensuring safe and efficient performance.

Corrosion Resistance: Often made from corrosion-resistant alloys or treated to enhance durability in harsh environments.

Precision Fit: The forging process allows for tight tolerances, ensuring that components fit together seamlessly.

Fatigue Resistance: The grain structure of forged materials helps resist fatigue, which is crucial for components subjected to cyclic loads.

Common Materials Used

Carbon Steel: Grades like A105 and Q345 are often used due to their balance of strength and cost-effectiveness.

Alloy Steel: Higher-grade alloy steels (e.g., 4140, 4340) may be used for high-performance applications, providing enhanced mechanical properties.

Stainless Steel: In environments prone to corrosion, stainless steels such as A182 F304 or F316 are preferred.

Applications

Oil and Gas Drilling: Essential for rotary drilling rigs, where mud pumps are used to circulate drilling fluid.

Mining: Used in similar applications where heavy-duty pumping systems are required.

Geothermal Projects: Employed in systems that require efficient fluid circulation under high temperatures.

Data Needed for Quotation

1) Your own drawing

2) Your requirement on material and necessary dimensional data

3) Ask for recommend

Common Materials for Forged Components:

Carbon Steel:

A350LF2、 A105、Q235、Q355D、A694F52、A516-GR65、EN10222、P280GH、P245GH、P250GH、JIS S25C、SS400、S20C、16Mn、C22.8、Q345B/C/D、1055、1045、C50、C45、10#、20#、35#、45#、40#、50#、60#

Stainless Steel:ASTM、A182、F304/304L、 F316/316L、 F316H、F310、 F321、JB4728-2000 、OCR18Ni10Ti、JB4728-2000、OCR17NI12Mo2、2205、2507、2103、904L、254SMD、304LN、316LN、1CR13、2cr13、3cr13、4cr13、321、302、W1813N、W2014N、W2018N、W2020N、P550、Cr18Mn18N

Alloy Steel:

42CrMo、A182F1、F5、F9、F11、F91、F92、F22、12Cr2Mo1、10Cr9Mo1VNbN(F91)、10Cr9MoW2VNbBN(F92)、JB4726-2000、15CrMo、JB4726-2000、12CrMoV、35CrMo、4140、4340、4330、4130、4150、9CR2MO、17NiCrMo6-4、18CrNiMo7-6、20MnMo、25CRMO、20CRMO、20CRMOTI、30CrNiMo8、34CRNIMO、34CrNiMo6、36CrNiMo4、34CrNi3Mo、34CrMo1、40CRNIMO、40CrNiMoA、50CrMo4、Q345D、300M、17-4PH、PH13-8Mo、15-5PH、 AerMet100

Special Steel:

ASTM182F51、S31803 、A182F309、Monel N04400、A182F310

Tool and Die Steel:

P20718、NAK80、S50C、4Cr13、3Cr17Mo、5CrNiMo、5CrMnMo、4Cr2NiMoV、S7、H10、H11、H12、H13、H13 MOD、 SUP H13、

D2、A2、A6、A8、O1、O2、9Cr2Mo、MC3、MC5、7Cr3、21CrMo10、1Cr17Ni2、310

Heat-Resistant Steel:

12CrlMoVG、P11、P22、P91、P92、F92、InconeI740H、CCA617、 Sanicro25

Bearing Steel:

G20CrNiMoA、G2CrNi2MoA、G20Cr2Ni4、GCr15、GCr15SiMn、GCr15SiMo、GCr18Mo、M50、M50NiL、CSS-F42L、 Cronidur30

Gear Steel:

42CrMo、20CrNi2Mo、34CrNi3Mo、40CrNiMo、20CrMnMo、35CrMo、18CrNiMo7-6

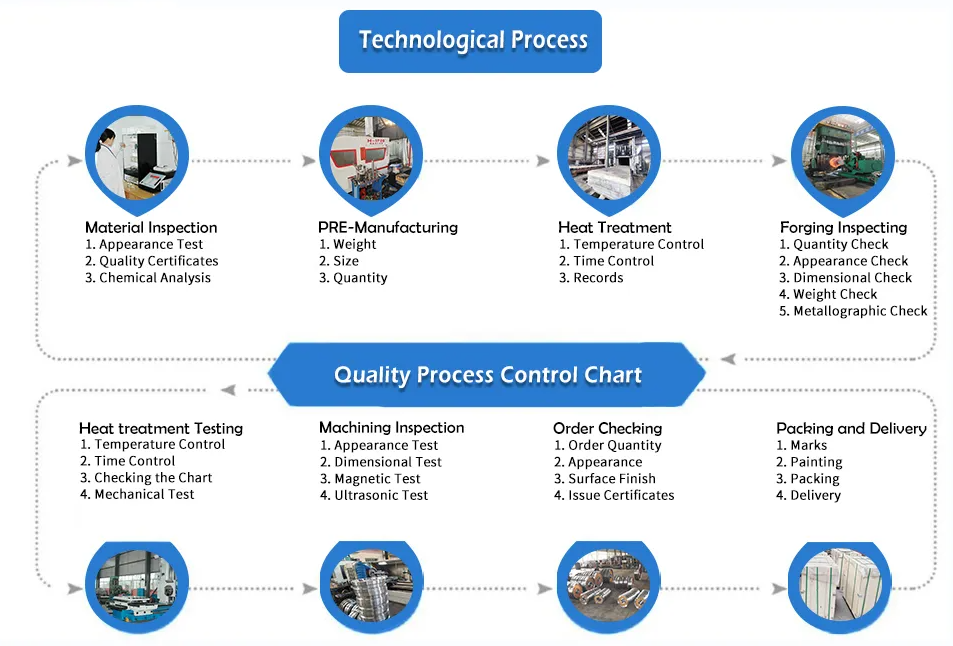

Processing technology:

Application areas:

Automotive transmissions, medical equipment, metallurgical machinery, lifting equipment, ore equipment, power equipment, light industry equipment, etc

Packaging :