PRODUCT CATEGORY

_1733156423.jpg)

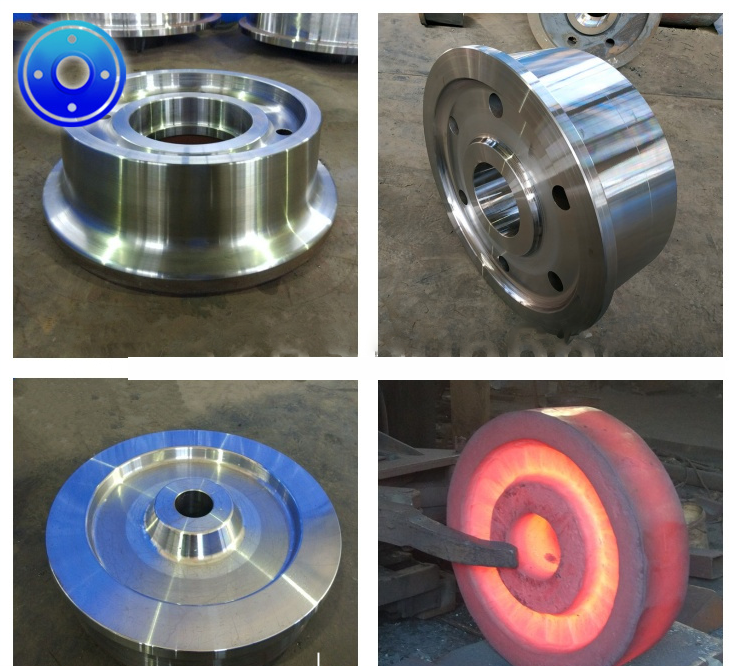

Forged Hook Wheels for Bridge Cranes

Forged Hook Wheels for Bridge Cranes

Forged hook wheels are specialized components used in bridge cranes, particularly designed to enhance lifting capabilities and ensure safety during operations. These wheels are integral for the movement of the crane along its tracks and for supporting heavy loads.

Material and Manufacturing:

Material:

Made from high-quality steel, forged hook wheels provide exceptional strength and durability.

The forging process significantly improves the material properties, making them resistant to wear and impact.

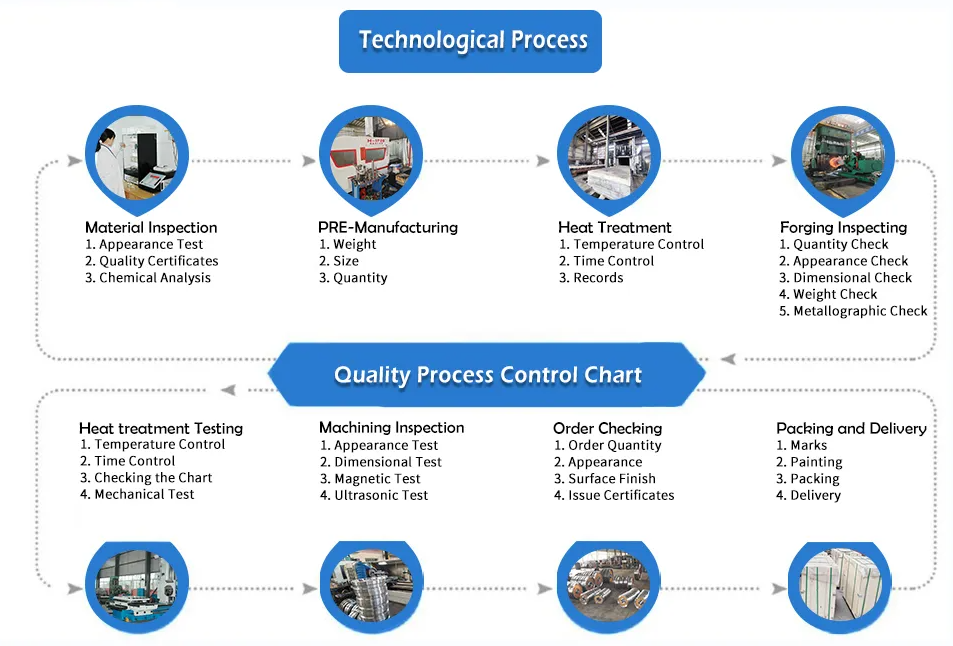

Manufacturing Process:

The wheels are manufactured through a high-temperature forging process that shapes the metal under considerable pressure.

This results in a solid, dense structure that can handle substantial operational loads.

Design Features:

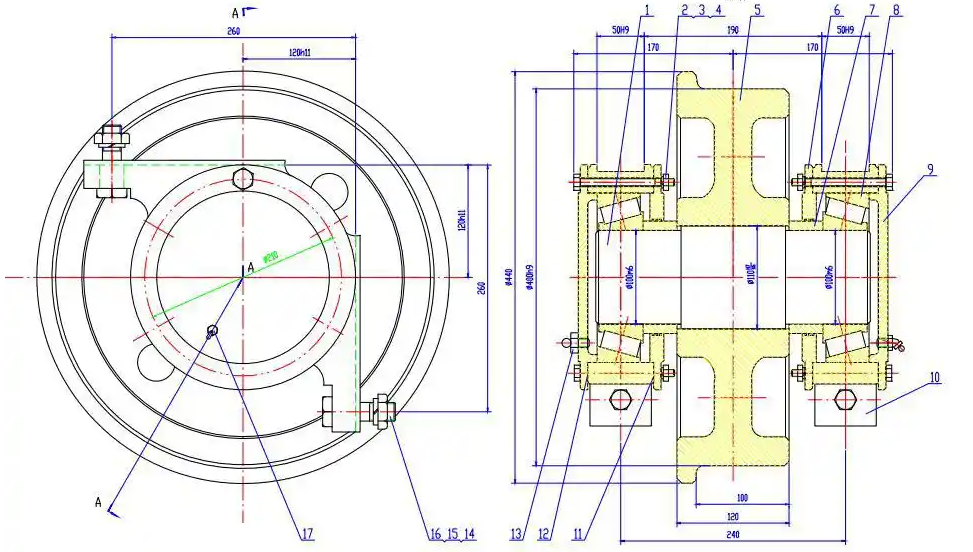

Shape and Size:

Wheels are designed to fit specific crane specifications, with variations in diameter and width to optimize performance.

Tread Design:

The tread is engineered for maximum traction, ensuring stability and safety during the crane's operation.

Hook Attachment:

Integrated hooks allow for secure attachment of lifting chains or cables, enhancing versatility in load handling.

Applications:

Forged hook wheels are utilized in various settings such as construction sites, manufacturing plants, and warehouses where heavy lifting is necessary.

Data Needed for Quotation

1) Your own drawing

2) Your requirement on material and necessary dimensional data

3) Ask for recommend

Processing Materials

| Case Hardened Comparison Table | |||||||

| GB | ГOCT | EN | DIN | W.N. | JIS | AISI/SAE | |

| 15CrMn | 16MnCr5 | 16MnCr5 | 1.7131 | 5115 | |||

| 20CrMn | 20MnCr5 | 20MnCr5 | 1.7147 | 5120 | |||

| 12CrMo | 12XM | 13CrMo44 | 1.7335 | 4119 | |||

| 15CrMo | 15XM | 15CrMo5 | 1.7262 | SCM415 | |||

| 20CrMo | 20XM | 20CrMo5 | 1.7264 | SCM420 | 4118 | ||

| 25CrMo | 30XM | 25CrMo4 | 1.7218 | ||||

| 30CrMo | SCM430 | 4130 | |||||

| 35CrMo | 35XM | 34CrMo4 | 1.722 | SCM435 | 4135 | ||

| 42CrMo | EN19 | 42CrMo4 | 1.7225 | SCM440 | 4140 | ||

| 50CrMo4 | 1.7228 | ||||||

| 40Cr | 40X | 41Cr4 | |||||

| 38XC | |||||||

| 25Cr2MoV | 25X2M1Φ | 24CrMoV55 | 1.7733 | ||||

| 50CrVA | 50CrV4 | 1.8159 | SUP10 | ||||

| 31CrMoV9 | 1.8519 | ||||||

| GCr15 | 100Cr6 | 100Cr6 | 1.3505 | 52100 | |||

| 20CrNiMo | 20XHM | 20NiCrMo2-2 | 21NiCrMo2 | 1.6523 | SNCM220 | 8620 | |

| 20XH3A | |||||||

| 20X2H4A | |||||||

| 17CrNiMo6 | 1.6587 | ||||||

| 18CrNiMo7-6 | 1.6587 | ||||||

| 34CrNiMo6 | 1.6582 | VCN150 | |||||

| 34NiCrMo16 | 35NiCrMo16 | 1.2766 | |||||

| 30CrNiMo8 | 1.658 | VCN200 | |||||

| 39NiCrMo3 | 1.651 | ||||||

| 34CrAlNi7 | 1.855 | ||||||

| 38CrMoAl | 38X2MОA | 41CrAlMo7 | 1.8509 | ||||

| 40CrNiMo | EN24 | 40NiCrMo8-4 | 1.6562 | SNCM439 | 4340 | ||

| 40CrNi | 40XH | 40NiCr6 | 1.5711 | ||||

| 20CrMnMo | 18XTM | SCM421 | |||||

| 40CrMnMo | 40XTM | SCM440 | |||||

| 30XTCA | |||||||

| 38XTH | |||||||

| 40XH2MA | |||||||

| 40X2H2MA | |||||||

| 38XH3MA | |||||||

| 38XH3MΦA | |||||||

Stainless Steel: ASTM, A182, F304/304L, F316/316L, F316H, F310, F321, JB4728-2000, OCR18Ni10Ti, JB4728-2000, OCR17NI12Mo2, 2205, 2507, 2103, 904L, 254SMD, 304LN, 316LN, 1CR13, 2cr13, 3cr13, 4cr13, 321, 302, W1813N, W2014N, W2018N, W2020N, P550, Cr18Mn18N and other forgings.

Heat resistant steel: forgings such as 12CrlMoVG, P11, P22, P91, P92, F92, InconeI740H, CCA617, Sanicro25 alloy, etc

Bearing steel: G20CrNiMoA, G2CrNi2MoA, G20Cr2Ni4, GCr15, GCr15SiMn, GCr15SiMo, GCr18Mo, M50, M50NiL, CSS-F42L, Cronidur30 and other forgings

Gear steel: forgings such as 42CrMo, 20CrNi2Mo, 34CrNi3Mo, 40CrNiMo, 20CrMnMo, 35CrMo, 18CrNiMo7-6, etc

Processing technology:

Application areas:

Automotive transmissions, medical equipment, metallurgical machinery, lifting equipment, ore equipment, power equipment, light industry equipment, etc

Packaging :