PRODUCT CATEGORY

Wind power main shaft

Wind power main shaft

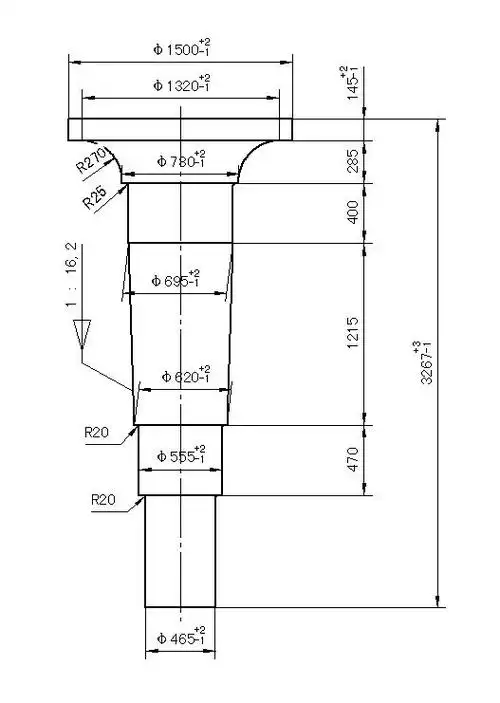

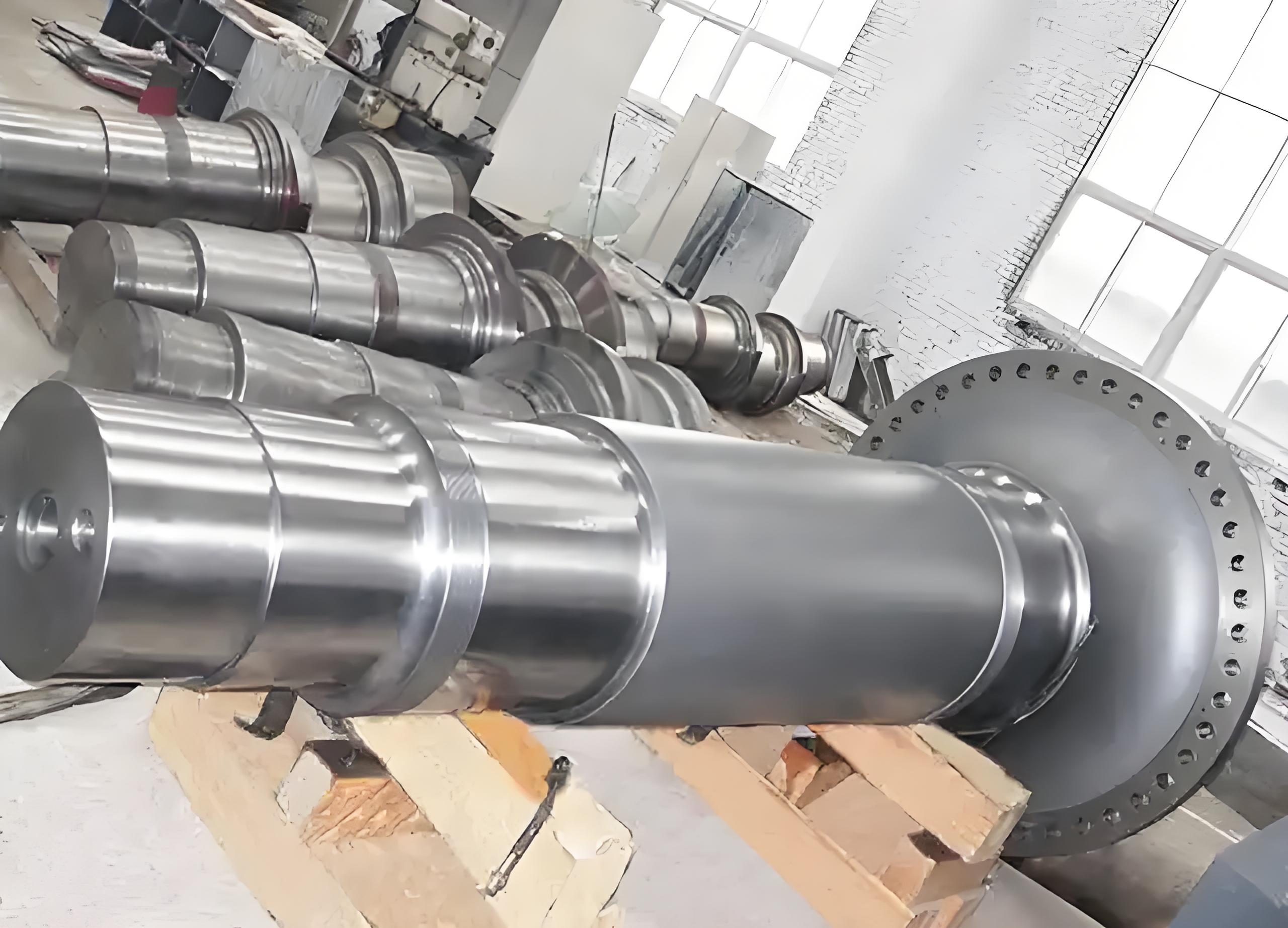

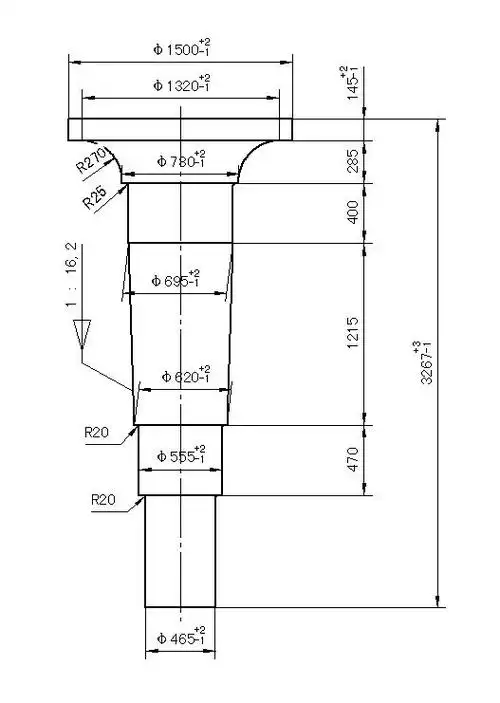

The main shaft of a wind turbine is a key component in the wind turbine system, mainly used to connect the blade hub and gearbox, transmit torque and force. The spindle bears complex alternating loads during the operation of the fan, so its fatigue strength directly affects the operational reliability of the fan

Structure and Material

The main shaft of wind turbines is usually made of stainless steel material, and the inner hole processing is difficult, requiring the use of deep hole drilling and boring machines for processing. The axial offset of the main shaft will be directly transmitted to the input shaft of the gearbox, and damage problems are usually repaired by welding, electroplating, and other methods. The material selection of the spindle is also very important. Commonly used materials include 42CrMoA or 34CrNiMo6, which need to have low-temperature impact resistance and cold brittleness resistance

Manufacturing process and maintenance

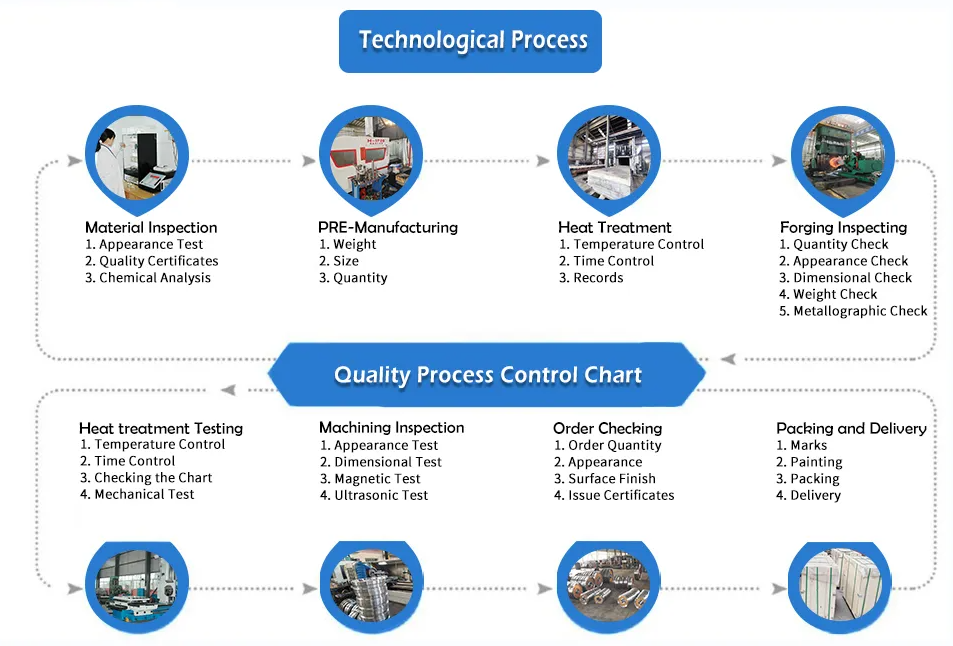

The manufacturing process of the spindle includes five steps: forging, heat treatment, rough machining, precision machining, and coating. In order to improve the reliability and durability of the spindle, advanced manufacturing technologies such as precision machining, heat treatment, and surface treatment will also be adopted. The design of the spindle needs to consider reliability and durability, especially in the case of high-speed rotation. High strength materials such as high-strength steel or aluminum alloy need to be selected, and lubrication and heat dissipation should be done well to extend its service life

Fatigue analysis

The main shaft of a wind turbine is subjected to complex alternating loads during operation, so its fatigue strength directly affects the operational reliability of the wind turbine. The spindle not only transmits torque, but also bears a certain bending moment load, so its fatigue failure belongs to multi axis fatigue 5.

Data Needed for Quotation

1) Your own drawing

2) Your requirement on material and necessary dimensional data

3) Ask for recommend

Processing Materials

| Case Hardened Comparison Table | ||||||

| GB | ГOCT | EN | DIN | W.N. | JIS | AISI/SAE |

| 15CrMn | 16MnCr5 | 16MnCr5 | 1.7131 | 5115 | ||

| 20CrMn | 20MnCr5 | 20MnCr5 | 1.7147 | 5120 | ||

| 12CrMo | 12XM | 13CrMo44 | 1.7335 | 4119 | ||

| 15CrMo | 15XM | 15CrMo5 | 1.7262 | SCM415 | ||

| 20CrMo | 20XM | 20CrMo5 | 1.7264 | SCM420 | 4118 | |

| 25CrMo | 30XM | 25CrMo4 | 1.7218 | |||

| 30CrMo | SCM430 | 4130 | ||||

| 35CrMo | 35XM | 34CrMo4 | 1.722 | SCM435 | 4135 | |

| 42CrMo | EN19 | 42CrMo4 | 1.7225 | SCM440 | 4140 | |

| 50CrMo4 | 1.7228 | |||||

| 40Cr | 40X | 41Cr4 | ||||

| 38XC | ||||||

| 25Cr2MoV | 25X2M1Φ | 24CrMoV55 | 1.7733 | |||

| 50CrVA | 50CrV4 | 1.8159 | SUP10 | |||

| 31CrMoV9 | 1.8519 | |||||

| GCr15 | 100Cr6 | 100Cr6 | 1.3505 | 52100 | ||

| 20CrNiMo | 20XHM | 20NiCrMo2-2 | 21NiCrMo2 | 1.6523 | SNCM220 | 8620 |

| 20XH3A | ||||||

| 20X2H4A | ||||||

Carbon steel: A350LF2, A105, Q235, Q355D, A694F52, A516-GR65, EN10222, P280GH, P245GH, P250GH, JIS S25C, SS400, S20C, 16Mn, C22.8, Q345B/C/D, 1055, 1045, C50, C45, 10 #, 20 #, 35 #, 45 #, 40 #, 50 #, 55 #, 60 # and other carbon steel forgings.

Stainless steel: ASTM, A182, F304/304L, F316/316L, F316H, F310, F321, JB4728-2000, OCR18Ni10Ti, JB4728-2000, OCR17NI12Mo2, 2205, 2507, 2103, 904L, 254SMD, 304LN, 316LN, 1CR13, 2cr13, 3cr13, 4cr13, 321, 302, W1813N, W2014N, W2018N, W2020N, P550, Cr18Mn18N, 06Cr19Ni10 (S30408), 022Cr19Ni10 (S30403), Cr1067Ni12Mo2 (S31608), Stainless steel forgings such as 022Cr17Ni12Mo2 (S31603), 06Cr25Ni20 (S31008), 06Cr18Ni11Ti (S32168), 022Cr19Ni13Mo (S31703), 0Cr17Ni4Cu4Nb, 06Cr19Ni10N, 14Cr17Ni2, 13Cr13Mo, 06Cr13, etc.

Alloy steel: 40Cr, 15CrMo, 20CrMo, 25CrMo, 30CrMo, 35CrMo, 35CrMoV, 42CrMo, 20Cr2Ni4, 20CrNiMo, 40CrNiMo, 30Cr2NiMo, 35CrMoV, 12Cr1MoV, 38CrMoAl, 18Cr2Nio4W, 40CrNi2Mo, 30CrMnSi, 25Cr2MoV, 17Cr2Ni2Mo, 20MnMo, 20MnMoNb, 34CrNi3Mo, 20CrMnTi, 40CrMnMo, 30Cr2Ni2Mo, 34CrMo1, 20CrMnMo, 24CrMoV, 30Cr2MoV, 34Cr2MoV Ni1Mo, 17Cr2Ni2Mo, 34CrNi3MoV, 20CrMnTi, A182F1, F5, F9, F11, F22, 12Cr2Mo1, 10Cr9Mo1VNbN (F91), 10Cr9MoW2VNbBN (F92), 12CrMoV, 4140, 4340, 4330, 4130, 4150, 9CR2MO, 17NiCrMo6-4, 18CrNiMo7-6, 30CrNiMo8, 34CRNMIMO, 34CrNiMo6, 36CrNiMo4, 34CrNi3Mo, 40CRNIMO, 40CrNiMoA, 50CrMo4, Q345D, 300M, 17-4PH, PH13-8Mo, 15-5PH, AerMet100 and other alloy steel forgings.

Special steel: custom forgings such as ASTM182F51, S31803, A182F309, Monel N04400, A182F310, etc.

Processing technology:

Application areas:

Automotive transmissions, medical equipment, metallurgical machinery, lifting equipment, ore equipment, power equipment, light industry equipment, etc

Packaging :